Roll Coating Nameplates

Roll Coating

Roll coating is the workhorse of aluminum decoration for automotive trim, appliance panels and nameplates. The process is used early in the decoration process to apply a primer before any litho printing or screen printing is applied. Overall color can also be applied with the roll coat process. Often the final step in the decorative process on metal is to apply a protective topcoat using the roll coating process.

Definition: Roll coating is the process of applying a coating to a flat substrate by passing it between rollers. Coating is applied by one auxiliary roller onto an application roll, which rolls across the conveyed flat substrate.

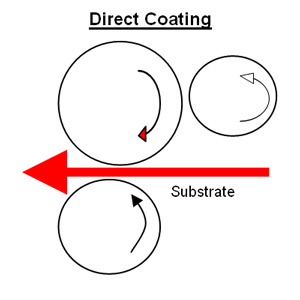

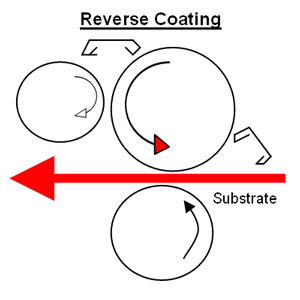

Roll coating is divided into two types: direct and reverse roll coating. In direct roll coating, the applicator roll rotates in the same direction as the substrate moves. In reverse roll coating, the applicator roll rotates in the opposite direction of the substrate.

Alternative names for Roll Coating are: Topcoat, Coating, Primer, Top Coating, and Coil Coating.

Roll Coating Advantages

•consistency in film thickness across the substrate, yielding high quality finish

•speed

•ability to run higher viscosity materials

•100% transfer efficiency

Roll Coating Options

•color

opaque or transparent

•gloss

high, medium or low

•substrates

metal

aluminum, steel, brass

plastic

abs, polycarbonate

•processes which can be combined with roll coat

screening (including textures or puff inks)

offset lithography

mechanical finishes (metal substrates)

•lensing

•diamond cut (metal substrates)

Roll Coating Considerations

•stock must be flat

•each coating must be cured before next process

•coatings are floods of an ink, they cannot be applied selectively

Alternative Processes

•Opaque and transparent colors: lithography, screening

•Topcoats: screening

Technical Information

•generally a faster process than screen printing, spray or lithography

•roll coating is limited to flatwork

•extremely film thickness sensitive

•viscosity dependent

•topcoat determines gloss level and provides protective qualities

•standard coating thickness:

Direct Coating - .05 to .15 mils

Reverse Coating - .2 to .6 mils

•Northern Engraving's topcoat chemistry's are generally polyurethanes, acrylics or epoxies

Additional questions and answers focusing on nameplate, label and badge design and manufacturing can be found on our Nameplate FAQ page.

Subscribe to Nameplate Blog

- 2021 (1)

- 3D (4)

- Adhesives (11)

- Aluminum (129)

- Aluminum In-mold (9)

- Aluminum Trim (41)

- Anodize (4)

- Appliance (12)

- Appliqué (5)

- Archive (35)

- Artwork Submission (4)

- Assembly (6)

- Automotive (35)

- Backlit (5)

- Boats (6)

- Brass (8)

- Brushed Aluminum (19)

- Carbon Fiber (2)

- Classic (1)

- Coined (5)

- Color Development (25)

- Computers (13)

- Cosmetics (24)

- Custom Patterns (11)

- Customization (16)

- Customized Patterns on Aluminum (2)

- Debossing (13)

- Diamond Cut (22)

- Digital Printing (2)

- ebook (4)

- Electronics (23)

- Embossing (53)

- Etched (20)

- Exterior (9)

- FAQ (29)

- Faux Finish (1)

- Faux Finishes (7)

- Favorite Nameplate (20)

- Furniture (9)

- Gauges (5)

- Gloss (4)

- Hang Tag (1)

- IDSA (1)

- In-mold Decoration (5)

- Individual Letters (7)

- Inlay (1)

- Key Fob (1)

- Labels (10)

- Large Vehicle (4)

- Laser Etch (2)

- Lithography (3)

- Match Box Cover (6)

- Materials and Processes (118)

- Mechanical Finishes (51)

- Medical Equipment (10)

- Metallic (8)

- Motorcycle (11)

- Nameplate (175)

- Nameplate Examples (54)

- Nameplate Tools (7)

- Outdoor Equipment (4)

- Overlay (7)

- Packaging (15)

- Patina Finish (3)

- Plastic (1)

- Plastic Trim (3)

- Point of Purchase (8)

- Polycarbonate (10)

- Process Color (16)

- Promotional Products (38)

- Prototypes (2)

- Recreational Vehicles (6)

- Resources (11)

- Safety Labels (2)

- Selective Patterns (10)

- Sill Plate (6)

- Sports Equipment (9)

- Stainless Steel (17)

- stock dies (10)

- Surfaces (4)

- Sustainability (1)

- Technical (1)

- Telecommunications (9)

- Testing (3)

- Texture (15)

- Top 10 (9)

- Woodgrain (2)