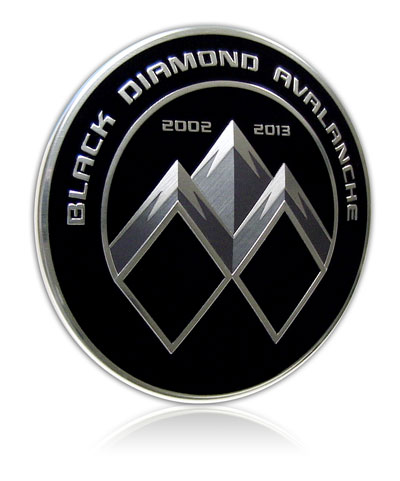

Precise Alignment for Exterior Automotive Badge

2013 Avalanche Black Diamond Badge

Alignment of product branding is a critical consideration in your design. Round dials pose the challenge of not having a flat edge and can easily become off-center. The 2013 Avalanche Black Diamond Badge illustrates one option among the many available for locating your badge on the product.

The attractive metal badge relies on sharp graphics aligned with a crisp emboss. The surface of the emblem has a slight dome and formed edge to add depth to the overall appearance. Further dimension is achieved with selective brush for a bevel-look depicting mountain peaks.

The molded backplate has keying features to help align the badge with its adhesive through the use of an assembly fixture. The aluminum in-mold process also provides increased dent resistance for the exterior application.

A challenge in the design of this part was assuring the alignment of the nameplate to the vehicle. This was done with an adhesive tab extending beyond the part which features the same holes as a foam carrier which lines up in the assembly fixture. The foam carrier surrounds the nameplate and registers the exact placement on the vehicle. The badge is held in place with the foam carrier via a plastic mask. The keying features of the backplate are used again to ensure the precise alignment onto the exterior of the vehicle. The plastic mask and foam carrier are easily removed and discarded during installation, requiring little fuss.

Does your next project need help with alignment? Let's talk!

Subscribe to Nameplate Blog

- 2021 (1)

- 3D (4)

- Adhesives (11)

- Aluminum (129)

- Aluminum In-mold (9)

- Aluminum Trim (41)

- Anodize (4)

- Appliance (12)

- Appliqué (5)

- Archive (35)

- Artwork Submission (4)

- Assembly (6)

- Automotive (35)

- Backlit (5)

- Boats (6)

- Brass (8)

- Brushed Aluminum (19)

- Carbon Fiber (2)

- Classic (1)

- Coined (5)

- Color Development (25)

- Computers (13)

- Cosmetics (24)

- Custom Patterns (11)

- Customization (16)

- Customized Patterns on Aluminum (2)

- Debossing (13)

- Diamond Cut (22)

- Digital Printing (2)

- ebook (4)

- Electronics (23)

- Embossing (53)

- Etched (20)

- Exterior (9)

- FAQ (29)

- Faux Finish (1)

- Faux Finishes (7)

- Favorite Nameplate (20)

- Furniture (9)

- Gauges (5)

- Gloss (4)

- Hang Tag (1)

- IDSA (1)

- In-mold Decoration (5)

- Individual Letters (7)

- Inlay (1)

- Key Fob (1)

- Labels (10)

- Large Vehicle (4)

- Laser Etch (2)

- Lithography (3)

- Match Box Cover (6)

- Materials and Processes (118)

- Mechanical Finishes (51)

- Medical Equipment (10)

- Metallic (8)

- Motorcycle (11)

- Nameplate (175)

- Nameplate Examples (54)

- Nameplate Tools (7)

- Outdoor Equipment (4)

- Overlay (7)

- Packaging (15)

- Patina Finish (3)

- Plastic (1)

- Plastic Trim (3)

- Point of Purchase (8)

- Polycarbonate (10)

- Process Color (16)

- Promotional Products (38)

- Prototypes (2)

- Recreational Vehicles (6)

- Resources (11)

- Safety Labels (2)

- Selective Patterns (10)

- Sill Plate (6)

- Sports Equipment (9)

- Stainless Steel (17)

- stock dies (10)

- Surfaces (4)

- Sustainability (1)

- Technical (1)

- Telecommunications (9)

- Testing (3)

- Texture (15)

- Top 10 (9)

- Woodgrain (2)